The Impact of Rapid Prototyping on Modern Business

In today's fast-paced business environment, staying ahead of the competition is crucial. One of the most game-changing methodologies that's gaining traction across various industries is rapid prototyping. This advanced technique not only accelerates product development cycles but also improves collaboration and innovation among teams. In this article, we will delve into the importance of rapid prototyping, especially for businesses in the realm of metal fabrication, like Deep Mould.

What is Rapid Prototyping?

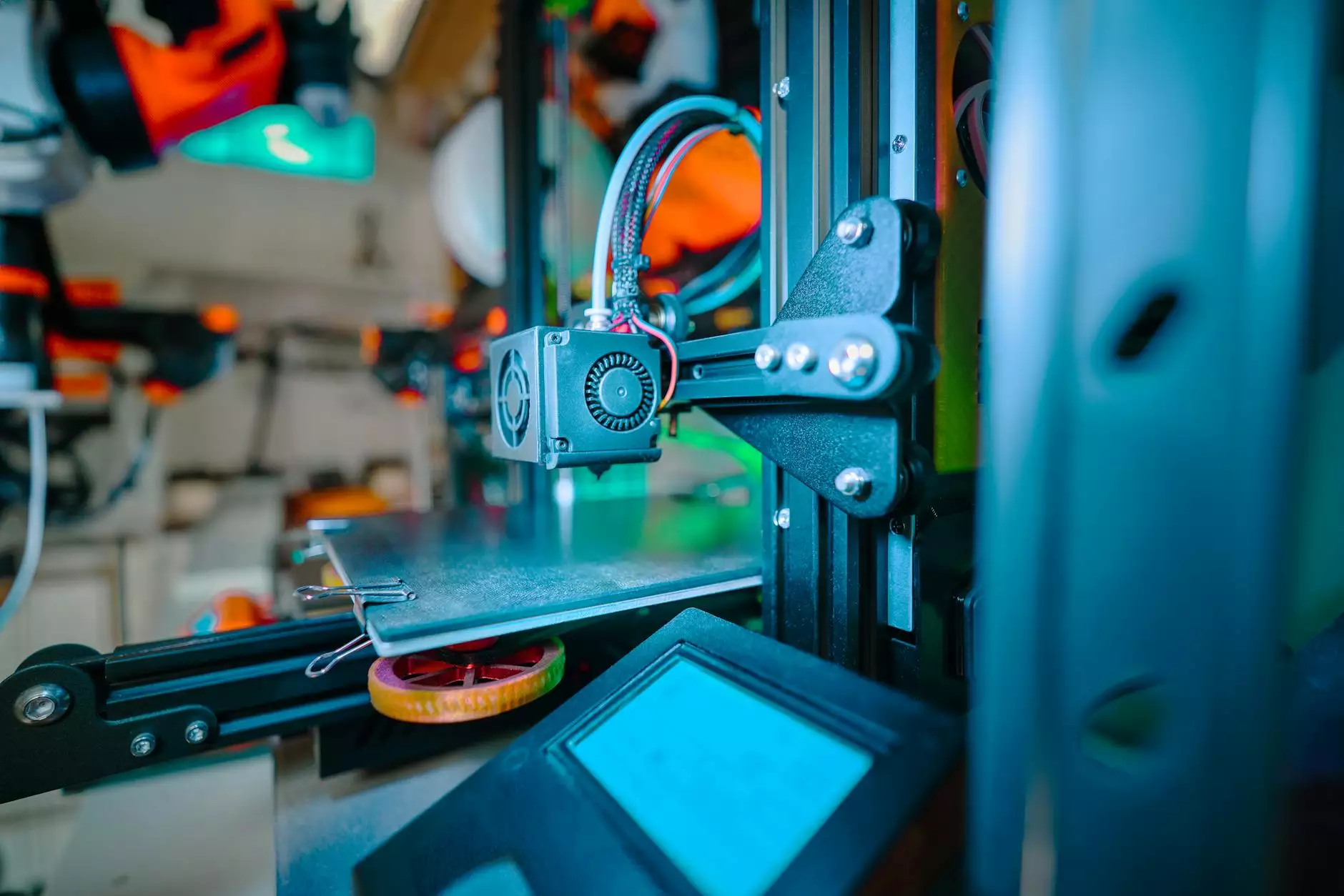

Rapid prototyping refers to a set of techniques used to quickly fabricate a scale model or a functional part of a product using 3D computer-aided design (CAD) data. This method allows businesses to create prototypes in a fraction of the time traditionally required, leading to enhanced agility and responsiveness in product development.

The Role of Rapid Prototyping in Metal Fabrication

In the realm of metal fabrication, rapid prototyping has opened up new avenues for innovation. Companies can produce intricate designs that were once impossible to achieve with conventional methods. Here’s how rapid prototyping is reshaping metal fabrication:

- Enhanced Design Flexibility: Engineers can quickly iterate on designs, enabling faster adjustments based on testing and feedback.

- Reduced Time to Market: By speeding up the prototyping phase, businesses can launch new products sooner, capitalizing on market opportunities.

- Cost Efficiency: Early identification of design flaws reduces the need for costly modifications during later production stages.

Benefits of Rapid Prototyping for Businesses

The advantages of implementing rapid prototyping in business operations extend beyond speeding up product development. Here are several benefits that can significantly impact an organization:

- Improved Collaboration: Teams can visualize concepts and ideas more effectively, leading to better collaboration among engineers, designers, and stakeholders.

- User-Centric Design: Rapid prototyping allows for the involvement of potential users during the development process, leading to better product-market fit.

- Iterative Testing: Prototypes can be tested and evaluated frequently, providing essential feedback that can guide subsequent design decisions.

- Innovation Enhancement: The pressure to innovate is relieved as companies can rapidly develop and test new ideas without significant investment risk.

- Environmentally Friendly: By utilizing materials judiciously in the rapid prototyping phase, businesses can minimize waste and enhance sustainability.

Applications of Rapid Prototyping in Various Industries

Rapid prototyping is not confined to the realm of metal fabrication; its applications span numerous industries:

Aerospace

Aerospace companies use rapid prototyping to develop lightweight components that enhance fuel efficiency. Prototypes can be tested in real-world conditions swiftly, ensuring that final designs meet rigorous standards.

Healthcare

In the medical field, rapid prototyping allows for the creation of custom implants and surgical tools tailored to individual patient needs. This personalized approach can lead to better surgical outcomes.

Automotive

The automotive industry benefits from rapid prototyping by enabling the quick development of complex parts and systems. This methodology helps manufacturers keep pace with consumer demands for innovation and performance.

How to Implement Rapid Prototyping in Your Business

If you're considering integrating rapid prototyping into your business model, here are key steps to follow:

1. Assess Your Needs

Analyze your current product development process to identify areas where rapid prototyping could provide maximum benefit.

2. Choose the Right Technology

There are various rapid prototyping technologies available, including 3D printing, CNC machining, and injection molding. Selecting the right technology will depend on your specific requirements.

3. Train Your Team

Invest in training your engineers and designers on rapid prototyping techniques and tools to ensure they can leverage this methodology effectively.

4. Start Small

Begin with less critical projects to allow your team to gain experience and optimize the prototyping process before tackling more complex projects.

Challenges and Solutions in Rapid Prototyping

While rapid prototyping offers numerous advantages, businesses may encounter challenges during implementation. Here are some common issues and their solutions:

1. High Initial Costs

Solution: Consider outsourcing rapid prototyping to specialized providers for initial projects to mitigate upfront costs.

2. Design Limitations

Solution: Collaborate closely with prototyping experts to explore design possibilities while considering the limitations of materials and technologies.

3. Balancing Speed with Quality

Solution: Establish a clear quality control process to ensure that rapid prototypes still meet necessary standards and specifications.

The Future of Rapid Prototyping in Business

As technology continues to evolve, rapid prototyping is expected to become even more sophisticated. Advancements in materials science, automation, and artificial intelligence will enhance the efficiencies of prototyping processes and the quality of end products.

The rise of additive manufacturing technology allows for the creation of complex geometries that traditional manufacturing methods cannot achieve. This shift is likely to redefine production norms across many industries.

Conclusion

In summary, rapid prototyping is a transformative force in the business landscape, particularly for companies focused on metal fabrication. By embracing this innovative methodology, businesses can improve their product development processes, enhance collaboration, and ultimately achieve greater success. Whether you are in aerospace, healthcare, or automotive, the benefits of rapid prototyping are evident, and the time to act is now.

To learn more about how Deep Mould can assist you in your prototyping and metal fabrication needs, visit deepmould.net.